|

A type of face where the grain patterns are matched at every veneer joint. Face is composed by turning over every other strip of veneer and joining them together. This produces a grain pattern that is matched at every veneer joint. The term book match refers to the veneer being matched just like the pages of a book.

|

| Effective Date | HWPW-VC | HWPW-CC | PB | MDF | Thin MDF |

| 1-1-2009 | P1: 0.08 | - | P1: 0.18 | P1: 0.21 | P1: 0.21 |

| 7-1-2009 | - | P1: 0.08 | - | - | - |

| 1-1-2010 | P2: 0.05 | - | - | - | - |

| 1-1-2011 | - | - | P2: 0.09 | P2: 0.11 | - |

| 1-1-2012 | - | - | - | - | P2: 0.13 |

| 7-1-2012 | - | P2: 0.05 | - | - | - |

FSC® controlled wood mitigates the risk of forest products originating from unacceptable sources (fsc.org/en/cw).

FSC® controlled wood requirements prohibit and are designed to avoid:

|

A plywood core structure composed of a veneer and MDFThis is a hybrid of veneer core and fiber core. The panel is constructed using a veneer core with the two cross-bands under the face and back veneer being a thin fiber core. This construction eliminates the problem of veneer telegraphing through the face veneer when finishing and produces a panel weighing considerably less than the fiber core.

|

| 4mm and thinner | +/- 0.2mm |

| 4mm - 7mm | +/- 0.3mm |

| 7mm - 20mm | +/- 0.4mm |

| 20mm and thicker | +/- 0.5mm |

| JAS | Average | Maximum |

| F4S | 0.3mg/L | 0.4mg/L |

| F3S | 0.5mg/L | 0.7mg/L |

| F2S | 1.5mg/L | 2.1mg/L |

| F1S | 5.0mg/L | 7.0mg/L |

| 4mm and thinner | +/- 0.2mm |

| 4mm - 7mm | +/- 0.3mm |

| 7mm - 20mm | +/- 0.4mm |

| 20mm and thicker | +/- 0.5mm |

|

Kraft paper is paper or paperboard (cardboard) produced from chemical pulp produced in Kraft process. Pulp produced by Kraft process is stronger than that made by other pulping processes. Kraft pulp is darker than other wood pulps, but it can be bleached to make very white pulp. Fully bleached Kraft pulp is used to make high quality paper where strength, whiteness and resistance to yellowing are important.

|

|

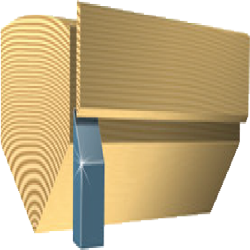

Lumber Core plywood consists of a face & back veneer, then a layer of crossband veneer, with the edge glued or finger jointed lumber in the center. Meranti, falcata, pine, rubber wood and other species are used for lumber core.

|

|

A plywood core structure composed of a medium density fiber board. A medium density fiberboard used as the core in the manufacture of the panel. This is a three-ply construction using a face veneer, a back veneer and the fiberboard as the core. This type of construction tends to produce the most stable panel. Fiber core construction also offers a void free core with excellent machinability. The fiber core with its super smooth surface provides a superior core for finishing the face and back veneer. The only real negative on fiber core construction is the weight of the panel produced. A typical ¾" thick plywood with fiber core will weigh approx. 100 lbs. 2 ply door skin is referred to construction of 1 ply MDF and 1 ply of face veneer.

|

|

By slicing parallel to the center of the log, a raised "cathedral effect" is formed by the innermost growth rings. The resulting cut is characterized by straight grain intermixed with cathedrals.

|

|

A plywood core structure composed of a particle board. This is where an industrial grade particleboard is used as the core in the manufacture of a panel. The construction of a panel is the same as fiber core. Particleboard core has the same advantages and disadvantages of fiber core with the exception of not having the same degree of machinability.

|

|

The slicing is made perpendicular to the annual growth rings of the tree. This creates a straight grain appearance. This method bisects annual growth rings and results in a straight grain appearance.

|

|

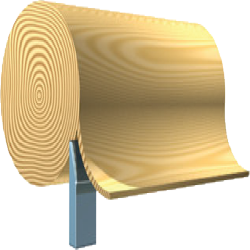

The log is centered on a lathe and turned against a broad cutting knife set into the log at a slight angle. Since this cut follows the log's annual growth rings, a wide, bold grain pattern is produced.

|

|

This straight grain cut is derived by slicing flitch at a slight angle to minimize the irregularities in the wood. This accentuates the vertical grain and minimized the flake. Rift cut veneers are more expensive due to lower yield from the log.

|

|

A type of face composed from adjacent veneer creating a repeated pattern. Face is composed by laying the veneer strips side by side and joining together to form the face without flipping leaves.

|

|

Type of plywood finish featuring a clear, durable top coating to add toughness, resisting to scrapes and chip. UV coating is basically a compound that is applied to wet wood and then instantly dried by ultraviolet light. Several different types of compounds are used to coat wood. UV finished surface is expected to reduce VOC (Volatile Organics Compounds) emissions. Different sheen level (or gloss level) is available such as UV50, UV40 and UV30. UV plywood is prefinished hardwood plywood panel featuring a clear, durable top coat, which will add toughness, resisting scrapes, chips and the effects of solvent wipe down to plywood.

|

|

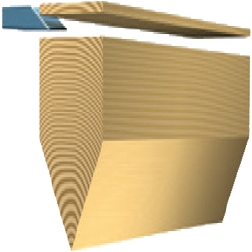

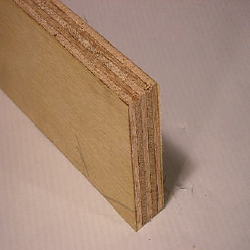

A plywood core structure composed of veneer sheets referred to as plies. This is the standard veneer cross-banding technique where an odd number of veneers are laminated together to produce the final panel. The number of veneers in a panel is referred to as the number of plies. Meranti VC gives more stability than poplar VC. Combi VC is referred to combination veneer core of mixed hardwood species and poplar veneer. 4 ply plywood is referred to construction of 3 ply VC and 1 ply of face veneer.

|